Plastic Film Capacitors

Types

Resources (PDF)

Downloads

Plastic Film Capacitors

For power electronics

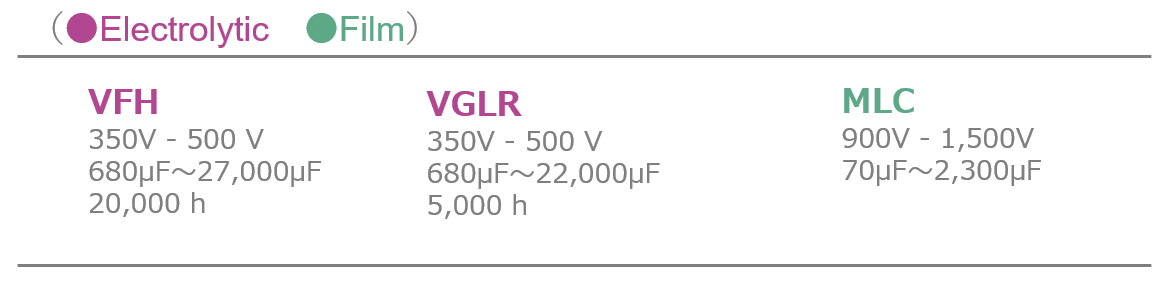

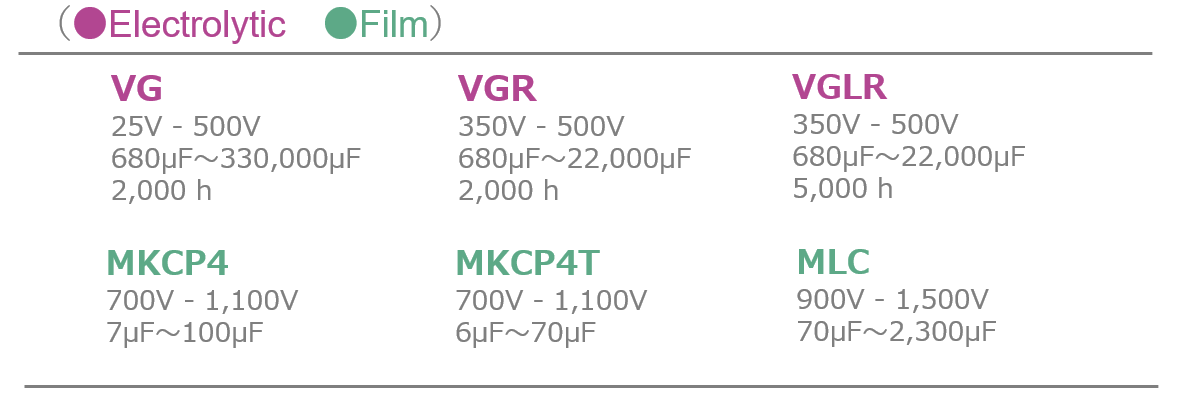

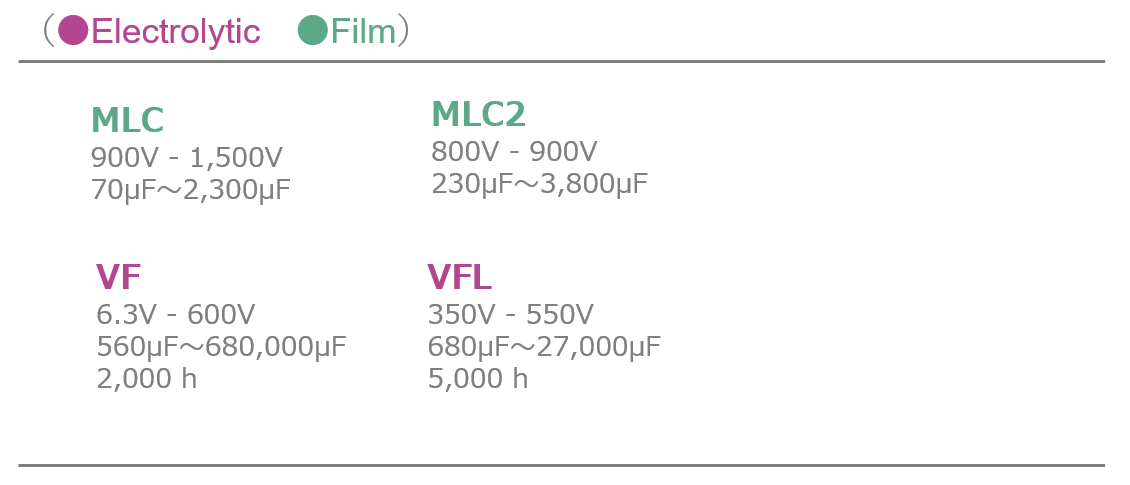

| Series | Feature | Operating Temperature range [℃] | Standard product | Small-sized product | High-reliability product | Rated voltage[V] | Capacitance range[µF] |

|---|---|---|---|---|---|---|---|

| MLC | Standard, For DC, Aluminium encased type | -40〜+85 | ◯ | ◯ | 900〜1,500 | 70〜2,300 | |

| MLC2 | Large capacitance, For DC, Aluminium encased type | -40〜+85 | ◯ | ◯ | 800, 900 | 230〜3,800 | |

| MLCA | High-ripple current, For DC, Aluminium encased type | -40〜+85 | ◯ | 600〜2,200 | 90〜5,000 | ||

| MKCP4 | Standard, For DC, Resin encased type | -40〜+85(105) | ◯ | ◯ | ◯ | 700〜1,100 | 7〜100 |

| MKCP4T | Humidity resistance, For DC, Resin encased type | -40〜+85(105) | ◯ | ◯ | ◯ | 700〜1,100 | 6〜70 |

| MKCA NEW! | Wide voltage range, For DC,Resin encased type | -40〜+85(105) | ◯ | ◯ | ◯ | 450〜1,200 | 1〜80 |

FAQs

What quality standards do these capacitors meet?

Our plastic film capacitors meet stringent quality standards, ensuring reliable performance across various applications. They are designed to operate within a temperature range of -40℃ to +85℃ (up to +105℃ for certain models), and some products, like the MKCP4T, offer enhanced humidity resistance. Additionally, all of our capacitors comply with environmental and safety regulations, including the RoHS directive, ensuring that they are free from hazardous substances.

Can these capacitors be customized for specific applications?

Yes, our capacitors can be customized to meet specific application requirements. Whether you need a product with higher capacitance, enhanced ripple current handling, or specific voltage ratings, we can tailor our capacitors to suit your unique needs. For example, our MLC2 series offers large capacitance options, and the MKCA series provides a wide voltage range, making them suitable for diverse applications.

How do AIC Tech's capacitors handle high ripple currents and what makes them suitable for such applications?

Our MLCA series is specifically designed to handle high ripple currents, making it ideal for demanding DC applications. These capacitors are encased in aluminum for superior heat dissipation, and their large capacitance range (90 to 5,000 µF) ensures stable performance even under high electrical loads. The design minimizes thermal stress, preventing issues like overheating and degradation over time.

How do AIC Tech's capacitors perform in harsh environmental conditions, such as high humidity or corrosive atmospheres?

Our capacitors, especially the MKCP4T series, are designed to withstand harsh environmental conditions such as high humidity. With their resin-encased design and extended operating temperature range (-40℃ to +85℃, up to +105℃), they offer enhanced durability in challenging environments. However, for corrosive atmospheres, proper environmental control and additional measures are advised, as corrosive elements like chlorides and sulfides may still affect performance.

Can these capacitors be used in applications involving high-frequency currents or harmonics?

Yes, AIC Tech’s capacitors are suitable for applications involving high-frequency currents or harmonics. They are designed to maintain stable performance across varying frequencies, with models like the MLC and MLC2 offering excellent performance for DC applications. However, harmonic distortion, especially at low (under 50 Hz) or high (above 10 kHz) frequencies, should be carefully monitored, as it may cause excessive heat generation. We recommend verifying the internal temperature of capacitors in such conditions.

What is the typical lifespan of these capacitors, and how does operating temperature affect their longevity?

Our capacitors are designed with a typical lifespan of approximately 15 to 20 years under proper operating conditions. However, operating at elevated temperatures can significantly reduce their longevity. For instance, when the internal temperature exceeds the maximum specified in the data sheet, the voltage rating needs to be derated to ensure stable performance and prolonged lifespan. Continuous monitoring of temperature, especially in high-ripple current applications, is essential for maintaining long-term reliability.

Are these capacitors compliant with environmental and safety standards, such as the RoHS directive?

Yes, all of our plastic film capacitors comply with the RoHS directive, ensuring that they are free from hazardous materials such as lead, mercury, and cadmium. Furthermore, our capacitors do not contain PCB or other banned toxic materials, making them environmentally friendly and safe for use across a wide range of applications.

Basics of Plastic Film Capacitors

What are plastic film capacitors?

Plastic film capacitors are a type of capacitor that uses plastic film as the dielectric material, which is essential for storing electrical energy. Compared to aluminum electrolytic capacitors, film capacitors offer more stable electrical performance across a wide range of temperatures, both high and low. They are also known for their ability to withstand higher voltages and have a significantly longer service life.

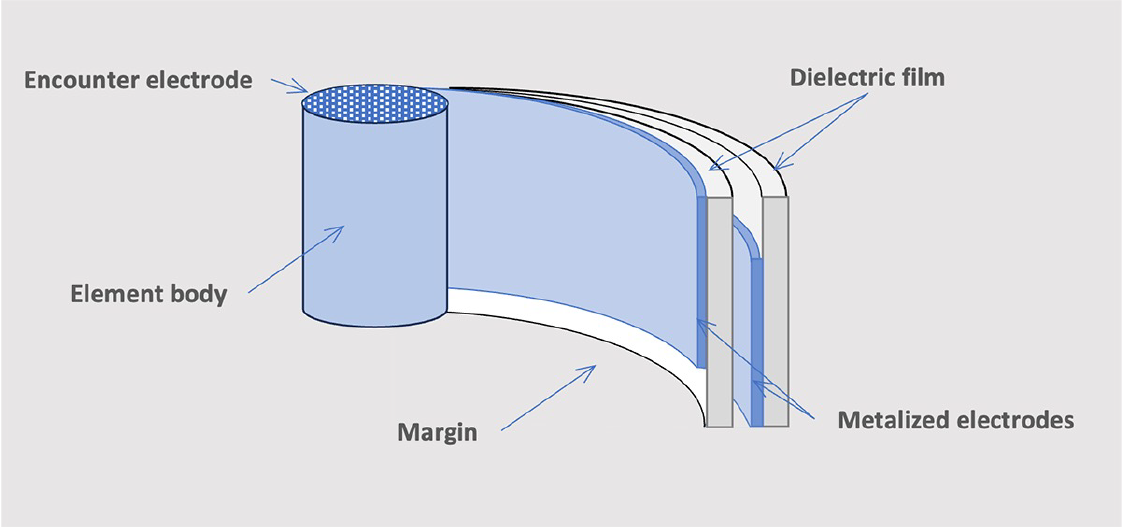

Structure of Plastic Film Capacitors

In a metalized-film capacitor, one or both sides of a thin plastic film (1–10 µm thick) are coated with a very thin metal layer (usually aluminum or zinc in pure or alloyed states, 20–100 nm). This film is then wound tightly to form the cylindrical “element body,” as shown in the image. Each turn of film includes a “margin,” where the metalized layer is intentionally absent, preventing unwanted short circuits at the edges. The electrodes—labeled “metalized electrodes” in the figure—overlap only in the central area (often called the “encounter electrode”), enabling the capacitor’s high capacitance. To make the capacitor terminals, exposed edges of the wound roll are “end sprayed” (e.g., with zinc), creating a conductive band to which leads or tabs are soldered or welded. This tight winding, combined with the thin metal coating, minimizes air gaps (voids) and helps ensure stable performance at high voltages, while optional “corona treatment” of the plastic film surface can further enhance adhesion of the metalized layer.

Comparing plastic film capacitors with other capacitor types

Differences from electrolytic capacitors

While aluminum electrolytic capacitors use a dielectric oxide film formed on aluminum foil as the anode and an electrolyte or conductive polymer as the cathode, plastic film capacitors use a plastic film as the dielectric material.

One of the major differences is in their performance across varying conditions.

Film capacitors provide more stable electrical performance over a wide range of temperatures, making them better suited for applications where temperature fluctuations are significant. They also have a longer service life and can withstand higher voltages compared to electrolytic capacitors.

In terms of size, while electrolytic capacitors can store large amounts of electricity even in smaller form factors, they rely on an electrolytic solution that can evaporate over time, reducing their lifespan and making them consumable parts that require periodic replacement. Plastic film capacitors, on the other hand, do not suffer from this aging process, offering greater longevity, though they tend to be bulkier, especially for higher capacitance needs.

Differences from ceramic capacitors

While ceramic capacitors use ceramic as the dielectric material and are made by layering ceramic and electrode materials, plastic film capacitors use a thin plastic film as the dielectric, which is wound to form the capacitor element. This difference in construction gives ceramic capacitors their characteristic small size, often just a few millimeters or less, making them ideal for compact digital circuits, like those found in smartphones.

In fact, a single smartphone can contain up to 1,000 ceramic capacitors due to their small size and mass production.

In contrast, plastic film capacitors are typically larger, especially for high-capacitance applications, and are better suited for circuits that require greater voltage tolerance, temperature stability, and longevity. While ceramic capacitors are commonly used in digital electronics due to their compact size and high production volumes, film capacitors are more commonly found in power electronics where stability, high-voltage performance, and extended service life are critical.

Differences from electric double-layer capacitors (EDLC)

EDLCs do not use a dielectric material like film capacitors do; instead, they store electric charge in the electric double layer formed between activated carbon electrodes and an electrolyte solution. This allows EDLCs to have an extremely large capacitance compared to other types of capacitors, making them more similar to batteries in terms of energy storage.

However, EDLCs have a much lower withstand voltage due to the absence of a dielectric, limiting their use in applications requiring high voltage. Instead, they are often used as power sources, with a focus on quick charging and discharging, similar to rechargeable batteries. Plastic film capacitors, on the other hand, excel in applications where higher voltage tolerance and stability are required, making them ideal for power electronics circuits rather than energy storage.

Common applications of plastic film capacitors

Motor Drives

Plastic film capacitors, such as our MLC series, are an excellent choice for high-voltage motor drive applications, offering superior performance in terms of stability, longevity, and voltage tolerance. While aluminum electrolytic capacitors are commonly used in motor drives for DC link circuits to remove ripple currents, plastic film capacitors can be employed for high-voltage applications requiring even greater reliability and longer service life.

In motor drives, the capacitor's role is to smooth out ripple currents generated from both the input (low-frequency) and inverter side (high-frequency). The MLC series, with its voltage range of 900V to 1,500V and capacitance range from 70µF to 2,300µF, provides a reliable solution for these high-voltage applications. These capacitors are ideal for industrial motor drives where stable operation under high electrical and thermal stress is crucial.

MLC: Operating at 900V to 1,500V with a capacitance range of 70µF to 2,300µF, the MLC series is ideal for motor drives that require high voltage and stable performance under high-ripple current conditions. These capacitors offer long life and excellent heat dissipation, ensuring reliable operation in both residential and industrial motor drives.

Renewable Energy Systems

In solar power generation, film capacitors are used in the DC link to smooth out ripple currents that are generated during power conversion. These capacitors help ensure the stable conversion of DC power from solar panels into AC power for the grid or household systems.

Plastic film capacitors are especially advantageous in applications that require high-voltage tolerance and long service life, which are critical in both solar and wind power systems. In solar inverters, for instance, they provide a stable energy buffer that allows smooth voltage conversion and improve the efficiency of power conversion. Their reliability and durability make them an excellent choice for maintaining consistent performance, even under fluctuating environmental conditions such as temperature variations.

In wind power systems, film capacitors are increasingly preferred due to their ability to handle large voltage fluctuations, especially in systems that utilize permanent magnet synchronous generators (PMSGs).

MKCP4: This resin-encased capacitor operates at voltages between 700V and 1,100V, with a capacitance range of 7µF to 100µF, making it ideal for high-voltage renewable energy applications like solar and wind inverters.

MKCP4T: A humidity-resistant version of the MKCP4, this capacitor is suited for harsher environments, offering the same voltage range (700V to 1,100V) and a capacitance range of 6µF to 70µF.

MLC: For higher-voltage applications, the MLC series operates at 900V to 1,500V, with a larger capacitance range of 70µF to 2,300µF, making it suitable for large-scale renewable energy installations that require high-capacity DC link capacitors.

Pulsed Power Supplies

In pulsed power supplies, the capacitor’s role is to buffer energy, ensuring that sufficient power is available during the pulse. Film capacitors are particularly advantageous in these applications due to their ability to handle frequent and rapid discharges with minimal voltage drop. Unlike aluminum electrolytic capacitors, which are more suited to applications where only partial discharge (30% to 40%) is needed, film capacitors excel in scenarios that require complete discharge for maximum energy transfer.

Another key feature of plastic film capacitors is their low equivalent series inductance (ESL), which is critical in pulsed power applications. A low ESL reduces the generation of transient signals during operation, allowing for more stable and efficient performance. This is particularly important in high-voltage industrial applications like arc welding, plasma generation, and X-ray systems, where consistent energy delivery and high reliability are essential.

MLC: For higher voltage applications, the MLC series operates at 900V to 1,500V with a capacitance range of 70µF to 2,300µF, making it well-suited for pulsed power applications that demand large energy storage and high voltage tolerance.

Traction Control Systems

In traction control, the electrical systems not only manage the driving force of the vehicle but also support critical functions like braking, lighting, and auxiliary power supply.

Inverters play a key role in controlling the power for electric motors in railcars. As the inverter cycles on and off, capacitors help to store and release energy efficiently, smoothing out the ripple current generated between the overhead wires and the inverter. This ripple current, which can vary between 8 kHz and 20 kHz, must be managed carefully to ensure the stable operation of the motor and minimize energy losses. Plastic film capacitors are particularly well-suited to this role due to their ability to handle high ripple currents, higher voltage tolerance, and lower energy losses compared to other types of capacitors.

Film capacitors also provide vital functions in auxiliary power supplies for electric railcars, acting as energy buffers to ensure the stable operation of auxiliary systems like lighting, HVAC, and onboard electronics. They also filter out high-frequency noise generated by inverters, preventing interference with the main power supply.

MLC: Operating at 900V to 1,500V with a capacitance range of 70µF to 2,300µF, the MLC series is a reliable choice for high-voltage applications like inverter-driven traction motors, providing excellent performance under high ripple current conditions.

MLC2: With a voltage range of 800V to 900V and capacitance from 230µF to 3,800µF, the MLC2 series is designed for large electric motor systems, where stable voltage control and minimal energy loss are crucial for efficient operation.

Guidelines for the Safe Use of Plastic Film Capacitors

1. Observe Rated Voltage and Overvoltage Events

Plastic film capacitors (MF-caps) are designed with a specific rated voltage to ensure reliable performance. Even though they can tolerate short-term voltage spikes up to about twice their rated voltage, repeatedly exceeding the rated voltage (particularly under high-temperature or high-ripple conditions) accelerates electrode corrosion or breakdown. Make sure to:

Choose a sufficient voltage margin: Derate the capacitor voltage if operating near the maximum ambient temperature or if large switching spikes and surges are expected.

Check for transient voltages: High dV/dt events, inrush currents, and switching surges can stress the thin metallized electrode, potentially leading to partial failures or open circuits.

2. Manage Ripple Current and Self-Heating

One of the most critical stresses for film capacitors in DC link or filtering roles is ripple current. The capacitor’s Equivalent Series Resistance (ESR) converts ripple current into heat, raising its core temperature (Tc). Excess self-heating degrades the polypropylene film and metallized layers more quickly.

Measure or model self-heating: Determine if the real operating ripple (including harmonics) causes the capacitor’s core temperature to exceed about 70 °C.

Avoid adjacent heat sources: Radiant heat from transformers, MOSFETs, or hot bus bars can push the capacitor beyond safe operating limits. Ensure adequate space or forced cooling.

Verify frequency impact: High-frequency harmonics above 10 kHz (or low-frequency components below 50 Hz) can create unexpected losses. Confirm the capacitor’s thermal performance under actual load conditions.

3. Self-Healing Behavior

Plastic film capacitors use a self-healing (SH) mechanism—minor dielectric breakdowns burn away the thin metal around the defect, isolating it and maintaining functionality. However:

Excessive defects: If large or repeated defects occur, self-healing may not be sufficient, potentially leading to carbonization and catastrophic failure.

Proper design margins: Keeping voltage, temperature, and ripple below or near nominal ratings lowers the frequency of self-healing events, reducing the risk of major breakdowns.

4. Environmental Considerations

Film capacitors are sensitive to moisture and harsh chemicals. The ultra-thin (20–100 nm) metalized layer can rapidly corrode in the presence of water, salts, or corrosive vapors.

Prevent condensation and liquid exposure: Avoid operation in environments subject to water, salt spray, oil, or conductive contaminants.

Control humidity: Many designs specify a maximum relative humidity of around 75%, with no condensation. If required, use resin-encased capacitors with improved moisture resistance.

Handle with care: Shipping fumigation or exposure to halides can corrode internal parts. Store and transport capacitors in sealed packaging if such treatments are anticipated.

5. Mechanical Mounting and Cooling

Ensuring proper installation is essential for both electrical and mechanical integrity.

Spacing and ventilation: Maintain sufficient gap (often 20–40 mm, depending on capacitor diameter) around the case to allow airflow and heat dissipation.

Orientation for liquid-filled units: If the capacitor has a viscous filling, mounting it upright with terminals facing upward helps prevent leakage. Resin-filled or dry capacitors can be mounted in any orientation.

Torque control: Use recommended tightening torques and washers on mounting studs or terminals; over-tightening can damage leads, while under-tightening may cause local overheating at the connection.

6. Series or Parallel Connections

In some high-voltage or high-capacitance applications, multiple capacitors must be connected in series or parallel.

Series connection: Unequal leakage currents can cause unbalanced voltages. A small resistor (voltage divider) across each capacitor helps maintain even voltage distribution.

Parallel connection: Differences in circuit paths or ESR can lead to uneven ripple current sharing; confirm that each capacitor remains within its rated ripple limit.

7. Derating for Reliability

Following manufacturer-provided derating curves helps ensure long service life:

Temperature derating: Operation above about 70 °C core temperature is not recommended. If operating at or near the maximum ambient temperature, consider lowering the voltage or ripple to keep internal losses in check.

Voltage derating: Applying a fraction of the rated voltage adds an additional safeguard against unexpected spikes and slows down electrode oxidation.

8. Lifetime and End-of-Life Management

Even with proper design and handling, all film capacitors have a finite service life:

Core temperature monitoring: If available, use built-in thermal sensors or attach thermocouples to assess real-time internal temperature.

Regular inspections and replacements: In high-stress or mission-critical applications, plan for periodic checks of capacitance and ESR. Although film capacitors often last 15–20 years, severe operating conditions may shorten this span.

Safe failure behavior: Film capacitors typically fail open-circuit or with decreased capacitance. However, severe overstress can cause plastic film ignition or rupture, so ensure surrounding enclosures and fusing are appropriately rated.